Do you know your ultimate cost of production?

Invest More in Your Grow Upfront

Startup costs for commercial cannabis cultivation sites can run well over $1 million in heavily regulated jurisdictions, while monthly expenses can easily stretch into six figures. Growing marijuana on a commercial scale simply is not cheap. In Canada, both wholesale and retail cannabis prices are falling in competitive areas with cannabis legislation. Similar trends will play out in jurisdictions around the world. This means that controlling costs is essential in order for cannabis cultivators to remain competitive. One way to get started, quickly? Cannabis SOPs. Check it out, thanks us later.

How can cultivators stay competitive in the cannabis market while continuing to produce high quality products with lower costs? Luckily there are several strategies to consider!

Currently, the majority of cannabis growers I talk to have started up their businesses for as little as possible with the intent to reinvest early crop revenues back into the business. While this seems like the logical approach agriculturally, it is a less robust approach from a manufacturing business perspective.

Growers should ideally be able to produce good quality cannabis for around a dollar per gram. That target isn't attainable with both haphazard decision-making, and unexpected supply and equipment costs. To help you with costs, take advantage of Canada's cannabis funding oppourtunity.

Before a site is selected, a robust business plan should be developed. Costs of better technology and automation inputs should be annualized and evaluated. Up front costs will be significantly greater, but unexpected costs will be minimized, which will attract more professional investors. Here are some high-dollar initial investments ideas that will pay off in the bigger scope of your cannabis cultivation business.

Wholesale cannabis prices are falling in competitive areas with cannabis legislation. This means that controlling costs is essential in order for cannabis cultivators to remain competitive.

Design a Cost-Efficient Cultivation Site

While outdoor cultivation may be ideal for hemp production, an enclosed grow space will avoid the environmental risks of mother nature. Greenhouses and indoor grows offer controlled environments that allow for measures to precisely manage crops and control risks.

Risk management evaluations are an important part of business planning and planning a quality management system with a quality assurance person. Risks need to be controlled by taking physical or procedural measures to mitigate their impacts. Here are just some of the factors a risk management plan should consider:

- Microorganisms like bacteria and fungi

- Pests like insects and rodents

- Cross-contamination from the outside environment

- Cross-contamination from within the facility

- Physical contamination like hair or jewelry that falls off workers or chunks of material from broken equipment

- Physical security and theft

- Chemical exposure to pesticides and nutrients

- Air quality (dust and airborne pathogens)

Proper site selection and building design can prevent risks from the start by designing quality into the cultivation facility. This is also a consideration if a facility is interested in GMP or EU GMP certification. EU GMP certification will require that these considerations have been made, and that the facility is designed in a way and using materials that are easily cleaned and sanitized. Absorbent materials such as wood should be avoided.

Well-designed grow facilities also consider the costs and benefits to cultivation and operating costs. Properly sealed grow spaces ensure plants are protected from environmental conditions such as heat and dryness. When selecting a site for a cannabis grow, consider some of these impacts:

- Distance to processing facilities

- Local energy and water ordinances

- Local climate vs climate control needs

- Accessibility to a labour market with appropriate local wages and skill in cultivation

- Distant enough from populated areas to avoid security risks

Designing a cost-efficient cultivation site requires one more consideration that will prove to be a common theme: energy efficiency. Using heat-absorbing flooring, proper insulation, and weather stripping will ensure that climate control systems do as little work as possible. Businesses may also want to consider installing solar panels and a backup generator to reduce energy costs and be prepared for power outages that could destroy crops.

Invest Early in Automation and Technology to Reduce Operational Costs

In business, metrics-based management is a gold standard that allows Lean and Six Sigma manufacturing principles to be applied. Being able to track cultivation activities in real-time, monitor growing environments, and run reports to compare factors like nutrient use and yield are vital to being able to continually improve your cultivation and business processes.

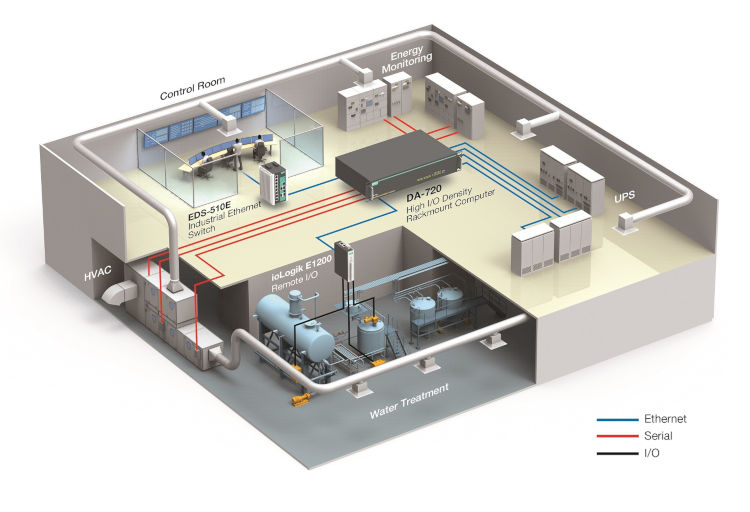

Production manufacturing traditionally implements software systems like ERPs. Cultivation software with environmental controls are also becoming popular. In addition to these two types of software, a business seeking to use best practices like EU GMP will need quality management software systems (QMSs) and document control software.

These are very costly software systems and ERPs like SAGE will require you to pay a programmer to customize the software and validate that it works as it should. Luckily, software suites like GrowerIQ are now available. These systems perform all the functions of an ERP, a QMS, a document control system, and cultivation and monitoring software, all in one validated package. GrowerIQ can be customized, but requires less cost and roll out time than trying to patch together several software suites to create one system.

Automation won't fully replace human labour when it comes to growing cannabis, but it can certainly reduce labour costs, improve control over the growing environment, provide precise metrics that report into a software tracking system, and precisely manage crops to reduce unnecessary inputs.

Luckily, software suites like GrowerIQ are now available. These systems perform all the functions of an ERP, a QMS, a document control system, and cultivation and monitoring software, all in one validated package.

What Can a Cannabis Grow Automate?

- Climate control

- Lighting

- Environmental monitoring

- Irrigation and fertigation

- Water treatment

- Trimming

- Grinding and processing

- Transplanting plants

- Moving plants

- Packaging

Bringing automation into some or all of these processes reduces the need for labour, increases manufacturing capacity, and optimizes processes. While human eyes and Master Grower experience is irreplaceable, automation decreases the need for manual labour so businesses can focus on investing in more efficient employees with higher skill levels. Automation will also maximize energy and cost efficiencies, provided everything is properly programmed and managed.

GrowerIQ's building automation control integration allows you to seamlessly connect your software to your facility.

Labour Efficiencies

We have already talked about how automation, technology, and smart growing systems can reduce labour costs. Employee productivity is another factor to consider that leads us back to the concepts of Lean and Six Sigma. Affordable online courses can educate business owners that do not come from a background in business or manufacturing and will help guide management in implementing policies and practices that keep efficiency in mind.

A Lean workplace efficiency model called 5S focuses on optimizing organization and workflow. The 5S system considers how small details like organization can improve efficiency. Even small factors like making sure workers have everything they need within arm's reach can cut down on movement and time waste.

Pay structure can also be used to improve labour efficiencies. Offering to pay bonuses for production of exemplary crops or offering dividends or shares in the company can increase employee buy-in and make employees feel more personally invested in their work.

You will also want to make sure that your cannabis cultivation business has a human resources department that can manage employee pay, benefits, and hiring. An HR generalist that can also act as an accountant is ideal for a smaller business. A larger cultivation business may need more staff to support management of employee resources and day-to-day financial accounting.

Implement a Proactive Pest Management Plan

Pesticides can cost many thousands per month and there is strong consumer concern over their use. For growers, there are very few pesticides that can be used indoors AND with cannabis, and pesticide testing must be passed with no residues remaining on the finished product.

Integrated pest management (IPM) is by far the best pest management system a cannabis grower could implement. When implemented properly IPM monitors pest trends, applies pest prevention and mitigation materials that will pose the least risk to workers, consumers, and plants, and then tracks trends of pesticide effectiveness to improve the pest management system for the future.

Three Big Ways to Prevent Pests and Pathogens

- Isolate grow room air supplies and avoid bringing in outside air

- Install air sanitation equipment to keep air in grow rooms clean and reduce the risk of bacteria or mould contaminating buds

- Keep the entire facility clean! All grow room equipment should be sterilized, and the room itself should be thoroughly cleaned between crops

GrowerIQ's experts will help you craft your Integrated Pest Management plan, and build that plan right into your operating procedures.

Connect to a Strong Vendor & Supplier Network

Building relationships with suppliers, and with the community around your site can lead to cost savings. Partnering with leading firms like GrowerIQ allows you access to preferred rates from leading vendors in our network. In general it is very important for cannabis companies to make good relationships with the community around them and encourage voters and city officials to embrace your facility as a valuable part of the local economy.

Don't waste your time calling around to source equipment that may or may not work with your setup. Your GrowerIQ contact has preferred vendor arrangements with all of the leading equipment manufacturers, to both get you the best deal, and ensure equipment interoperability.

Some other factors to consider are around equipment and supply maintenance. Preventative maintenance on expensive facility and equipment will pay for itself very quickly. For example, checking lighting levels to ensure bulbs are replaced and cleaned on a suitable schedule. Cleaning and maintaining the facility and equipment will preserve their value, optimize performance, and extend their lifespan.

Evaluate Business Structure and Scope

With the value of dried flower in juristdictions around Canada dropping at an alarming rate, and many US states reporting over-supply, it is more important than ever that cultivation businesses start off with a robust business model. Vertical integration, or performing more steps in the supply and processing chain, can add value and reduce costs to your business. Here are some examples:

- Cleaning your own biomass will reduce extraction costs

- Extracting your own biomass eliminates middlemen and transportation

- Producing finished products that can be white-labeled and sold at wholesale

- Offering your own line of products at retail prices in addition to white-labeling

The GrowerIQ consulting team can help you with logical inputs to draft a solid business plan. As you add more business capabilities to the process, you increase your ability to offer goods and services. If the market fluctuates in demand for a product from one or another stage of processing, your business can respond by scaling up that portion of the business.

Vertical integration also offers more control over product quality and results in fewer costs for transportation and processing. It is also important to have the ability to scale your business up or down as needed. If your systems are particularly successful, there is potential for added revenue in consulting and setting up more cultivation sites.

One last consideration of business scope and structure is the plants themselves. Being able to offer hemp and marijuana maximizes the ability of a business to participate in both the CBD and THC markets. If there is more demand for CBD than marijuana, being able to increase production of one can help balance downturns in the other market.

Choosing local genetics to work with is also advantageous. It is yet another way to invest in the community you are doing business in, and focus on growing strains that perform best in that locality. These strains will require fewer inputs and maximize yields.

The literal structure of your cultivation site is also important because every plantable square foot is valuable. Luckily we live in a three dimensional world where cubic feet can add plantable space. Vertical growing space should be utilized whenever possible. While more mature plants are often too large and heavy to place in vertical configurations, clones, seedlings, and plants in early vegetative growth can often be stacked on shelves with lighting hanging from the shelf above.

Thoroughly Evaluate Energy Efficiency

Cannabis consumers are often people who are very concerned with the health of the environment, and the need for energy conservation and sustainable resource use. Colorado Public Radio's segment "On Something" did a July 30, 2019 report on the carbon footprint of cannabis. Climate change is an extremely important issue and the high cost of energy to grow cannabis is well known. Energy efficiency is one of the most important ways to reduce operational costs in a commercial cannabis grow, and being a green grower could give you a unique market differentiator.

Site Selection and Utilities

In some localities, cultivators could end up fined or paying extremely high costs for excessive energy use. Before finalizing your site, contact the team at GrowerIQ to run through the site selection checklist. It's easier to prevent expensive mistakes before you secure your land than after! Additionally, ensuring your clocks and timers are synchronized with the utility company is essential. In areas without these premiums, controlling lighting schedules to operate more on non-peak use times may also reduce energy costs.

Considering electricity costs should also be a factor in site selection. Finding a location with a climate that demands less energy use and charges less for the energy that is used can have a major impact on monthly costs.

Manipulate Your Light Cycle

Operating lighting on non-peak hours may help offset some energy costs, but manipulating the light cycles altogether can have big financial impacts. Cannabis is a short day plant that switches from vegetative growth to flowering growth when light is reduced to 12 hours.

Indoor cultivated plants can be tricked into thinking it is time to flower by reducing light exposure. This can shorten cropping times and allow for more cultivation cycles. There are also lighting techniques like the gas lantern routine or interruptive lighting that can be used to further reduce light use and manipulate cropping times.

Manipulating your lighting schedules can have a tremendous impact on both energy costs and crop quality.

Climate Control and Energy Conservation

When the grow lights go on, the HVAC system also turns on to mitigate the heat produced by the lighting. Facilities with energy efficient building supplies and insulation will use less energy to operate their HVAC. Installing energy efficient HVAC systems that are automated to run responsively to the crop will increase energy efficiency even more. Our partner HVAC and building controls suppliers have decades of experience in selecting the right equipment for the space. The takeaway is to engage GrowerIQ early in your project to ensure all the pieces of the puzzle fit together.

How to Audit Energy Usage

Simple calculations can be used to audit energy use. Measuring the facility's actual energy use is the first step to improving energy efficiency. Several types of sensors and meters can be used with (or without) software to track their readings to gather data for calculating energy efficiency.

Calculating Energy Use for Lighting and HVAC

- Multiply the wattage of the lights by how many hours a day they are used

- This amount can then be deducted from the energy bill

- The amount left is generally how much the HVAC system and environmental controls cost to operate

Optimizing Commercial Cannabis Lighting

Lighting can account for about 33% of overall energy usage in a cultivation facility. To optimize lighting, cultivators need to calculate the photosynthetic photon flux density (PPFD) and daily light integral (DLI). PPFD measures the number of photons in the visible light spectrum that fall on the plants per second, while DLI measures the amount of light the plants receive in a day.

Average DLI is generally around 35 moles per square meter per day. If plants are receiving more light than necessary, adjustments can be made that will reduce electricity use. Optimized lighting may vary based on the strain you are growing, so keep track of trends by batch and by strain, or use a software system like GrowerIQ that can integrate with your lighting equipment and report the trends to you.

While one strain may perform better with 18 hours of light during vegetative growth, another may only need 16 hours of light. As long as it is receiving more than 12 hours of light the plant will not enter floral growth, but it is good to leave a couple of hours to buffer the photoperiod. DLI and PPFD readings will also tell growers if supplemental lighting is needed. If you prefer to forgo the complexities of light analysis, our team can take care of the details with our lighting partners - leaving you free to concentrate on producing high quality product.

While one strain may perform better with 18 hours of light during vegetative growth, another may only need 16 hours of light. As long as it is receiving more than 12 hours of light the plant will not enter floral growth, but it is good to leave a couple of hours to buffer the photoperiod.

More Lighting Efficiency Tips

- Use fresh bulbs and replace them on the manufacturer's recommended schedule

- Single-ended high pressure sodium (HPS) bulbs are the least efficient bulb type

- Double-ended bulbs can result in up to a 30% increase in light output within PAR using as much energy as a single-ended HPS

- A double-ended bulb can easily cover a 5'x5' area instead of a traditional 4'x4' area, reducing overall need for lighting

- Light that hits the walls or floor of the grow room is wasted, reflective material or titanium white walls and flooring can help bring that light back to the plants

- Reflectors on the light ballasts should be replaced if damaged, and cleaned regularly

Evaporation and Energy Use

Vapour pressure deficit (VPD) indicates the evaporation potential of water into the air. VPD is in most basic terms the difference between relative humidity and air temperature. This number can be used to find the optimum climate for plants to maximize photosynthesis. Climate controls can then be adjusted to maintain plants at their ideal VPD. Seasonal adjustments will have to be considered, but optimizing environment for VPD can reduce energy costs while increasing plant quality.

In order to optimize the growing environment, having an integrated climate control system is vital. As discussed earlier, integrating climate controls to a controller box, and to management software, allows the system to act responsively to conditions as they change and tracks use metrics that can be analyzed.

Energy Efficient Cannabis Cultivation Equipment

Whenever possible, use equipment with variable settings and high energy efficiency ratings. From fans to lighting, the ability to turn equipment up and down as needed ensures you are not using excess resources. When equipment has variable speeds it reduces the amperage it draws. It can also help keep plants from being shocked by climate controls turning on and off by gradually running them up and down to influence temperature and humidity.

Choosing efficient fans is another important equipment consideration. Exhaust fans should have a large diameter and a small motor that has a ventilation efficiency factor above 15. Fan efficiency is rated in cubic feet per minute (CFM). When fans have an efficiency factor above 15, they will have an extremely efficient motor that provides the power to have sufficient air changes while drawing less electricity.

Staggering equipment further reduces energy peaks. If you start temperature control by first turning on fans and exhaust, it will use less energy than the HVAC system. A second HVAC stage can then be turned on if the temperature adjustment is not met by fans or exhaust. This way power is used only as necessary and peaks do not occur from turning on several units all at once.

If a facility is designed to have multiple small grow rooms, lights can be staggered so that they are on opposite intervals and in 15 minute increments to keep them all from running at the same time and creating energy peaks.

What is the Best Way to Heat Commercial Cannabis Grows?

Geothermal heating is by far the most efficient way to heat a commercial cannabis grow. Once again, the benefits of comprehensive planning make themselves clear. GrowerIQ's subject matter experts can ensure you start with the correct facility design and equipment right from the beginning. These floor-embedded heating systems are perfect for targeting the roots of the plant. By targeting the roots, the ambient room temperature can be cooler and the plants will still be happy. Geothermal heating is especially important if plants are to be grown in a greenhouse in a location that experiences cold climates.

The Takeaway

Energy efficiency is one of the most important factors in reducing operational costs in a commercial cannabis grow. Businesses can do more by getting it right and investing more from the start. Taking this path will make it harder to enter the cannabis market, but will make your business have lasting power in the industry by avoiding higher costs down the road.

Finally, commercial cannabis growers must remember that their business is engaged in both agriculture and manufacturing. Applying systems like GrowerIQ's cannabis cultivation software that can gather metrics, and using business management strategies like Lean and Six Sigma will instill an operational management culture that seeks to reduce costs while improving efficiency and quality.

Not sure where to begin? GrowerIQ makes the process simple. Start now by submitting the form to the right, or chat with us. For more information, and actionable tips from our Master Grower on how to improve your yields and processes, visit our knowledge portal, What's Growing On?

About GrowerIQ

GrowerIQ is changing the way producers use software - transforming a regulatory requirement into a robust platform to learn, analyze, and improve performance.

To find out more about GrowerIQ and how we can help, fill out the form to the right, start a chat, or contact us.