First, what are your business goals?

With so many different extraction techniques available and seemingly all of them boasting to be "the best," it can be difficult to decide which type of extraction to add to your next cannabis SOPs (cannabis standard operating procedures). Regardless of which method you choose, large scale extraction setups are a costly investment. No one wants to invest heavily in something without having a great deal of confidence that the investment will pay off in the long run.

So which extraction method should you choose? First you must decide what your goals for extraction are. Each different extraction method results in a slightly different product. There are also differences between methods including time spent on extraction, and purity of extraction. Because of this, it is important to keep in mind what your goals are and to select an extraction method serving those goals.

Artisanal Extracts

Some extraction methods are utilized for the quality and desirability of the final product. Extraction methods such as bubble bags and rosin presses will deliver artisanal results. The products of these extracts are extremely flavourful and many cannabis purists will choose these types of extracts over those made with organic extraction solvents.

Rosin, the Leader in Solventless Extracts

Rosin press hash is as much like an art form as it is an extraction process. Rosin presses use heat and pressure to liquify the cannabinoids and to press them out of the plant material. The heat and pressures used can vary and this is where the art aspect comes in.

Rosin is typically a low yield extraction method that produces extracts which maintains many of the flavour qualities that the cannabis flower has. The high quality of the extracts along with the absence of solvents in the extraction method make this an appealing product to many cannabis consumers.

The low yield and lower cannabinoid potency extracts resulting from this method makes it difficult for a team without an extractionist with a significant amount of experience in this method.

Bubble Bags, the Classic Extraction Method

Much of what was said about rosin press hash products also applies to water hash products. The method produces a lower cannabinoid potency extract that appeals to cannabis users looking to avoid extracts made with organic solvents.

Bubble hash differs from rosin hash greatly in the way in which it is made. Compared to many other forms of hash, bubble hash is quite labour intensive. Technology for large scale bubble hash making is not on par with other large scale extraction methods.

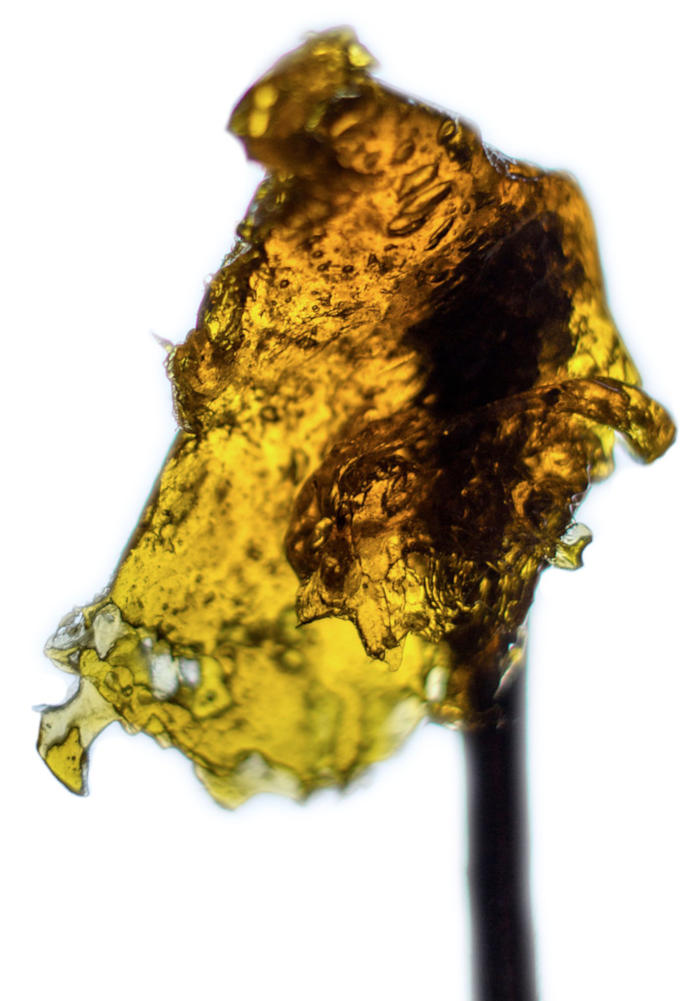

Cannabis extraction methods can vary, resulting in differing levels of taste and quality. Rosin pictured above.

Pros and Cons

Due to production constraints associated with bubble hash and rosin press extracts, these methods are typically not done on the same scale as hydrocarbon extraction, CO2 extraction, or ethanol extraction.

The resulting flavourful extracts as well as the fact that potentially harmful solvents never touch these products, mean there will always be a market for these types of extracts. That market will however likely always remain relatively small, much like the extraction capacity of these methods. These methods are for those who want to make high quality niche products and do not mind the time and effort required to master these methods.

Large-Scale Production

When it comes to large scale cannabis extract production there are three main types: hydrocarbon, CO2, and ethanol extractions. One could argue that when talking about really large-scale extraction throughput, it comes down to either ethanol or supercritical CO2.

For the sake of this article we will consider anything over 20 pound batches to be large-scale even though many hemp extraction labs process quantities large enough that 20 pounds is considered extremely small.

Using hydrocarbon solvents for extraction is dangerous. These are highly flammable gases that have the potential to explode if handled incorrectly.

Large-Scale Ethanol Extraction

For those hemp extractors looking to extract thousands of pounds of hemp within a few months after harvest there really is no substitute for ethanol extraction. In terms of extraction throughput, ethanol is the easiest extraction method to scale up. The downfall of using ethanol extraction is that the extracts are not as pure as other extraction methods.

Unlike hydrocarbon solvents or CO2, ethanol is a polar solvent which means that it pulls more polar compounds, as well as the nonpolar cannabinoids and terpenes, out of the plant material. Because of this, ethanol extracts will typically require some post-extraction processing in order to achieve a shelf-worthy final product.

This is a good time to mention that in the hemp industry many of the products that are made for consumers such as tinctures, capsules, and topical products are often made with the crude ethanol extract of hemp. The variety of uses for hemp crude extract creates a large market for bulk crude ethanol extract, even though it is not a shelf-worthy final product in itself.

Hydrocarbon Extraction Provides a Diversity of Products

Hydrocarbon extraction is often employed in the recreational cannabis industry due to the large variety of products that can be made from hydrocarbon extractions. Wax, shatter, sugar wax, terp sauce and diamonds are all products that can be made from hydrocarbon extraction.

The big difference between these different products comes from how they are handled post extraction. For instance, introducing mechanical agitation while purging of the residual solvent will result in a thick wax to set up. Conversely, limiting the amount of agitation of a dewaxed extract while purging the residual solvent will allow the extract to set up in a solid slab of shatter that is transparent.

While the quality of products made from hydrocarbon extraction is top of the line within the industry, there are also significant hazards that must be taken into consideration. Using hydrocarbon solvents for extraction is dangerous. These are highly flammable gases that have the potential to explode if handled incorrectly.

Storing large tanks of gases must be done in a very controlled environment that includes having all of the chemicals locked in fire safe cabinets. The dangers associated with hydrocarbon extracts also limit the scale of extraction, considering that the dangers scale proportionally to the volume of hydrocarbon solvents used.

The Tunability of CO2 Extraction

CO2 extraction is widely employed in both recreational cannabis and hemp industries. The reason for the broad applications of CO2 extraction is due to the tunability of CO2 as an extraction solvent.

By adjusting the temperature and pressure of the CO2 extraction, it is possible to modify which compounds will be extracted. This allows extractors to run multiple passes on the same material to extract different compounds with each pass. This enables extractors to choose between runs offering higher purity extracts by sacrificing yields or runs with higher yields with a sacrifice in purity.

It doesn’t have to be a choice however, as extractors can run a high purity run at subcritical conditions and then run a high yield run at supercritical conditions. This tunability emphasizes the power of CO2 as an extraction solvent.

When CO2 is run in subcritical conditions, the solubility of many of the plant compounds is reduced; including unwanted compounds such as chlorophyll. Alternatively when CO2 is run under supercritical conditions, the solubility of many of the compounds, including chlorophyll, is increased, meaning more compounds are removed from the plant material.

It is not uncommon for extraction companies to vary the temperature and pressure of CO2 extractions for different products. Often companies aiming to produce high quality vape pens will run an initial pass on the material to first extract just the plant terpenes.

They will then run a second pass increasing the temperature and or pressure of the extract to remove the cannabinoids in a subcritical extraction. The two passes can then be mixed back together for use for vape pens.

The same extractor might then run a supercritical pass on the material to remove any remaining cannabinoids and other plant compounds, such as flavonoids that have therapeutic properties, for use in topical compounds.

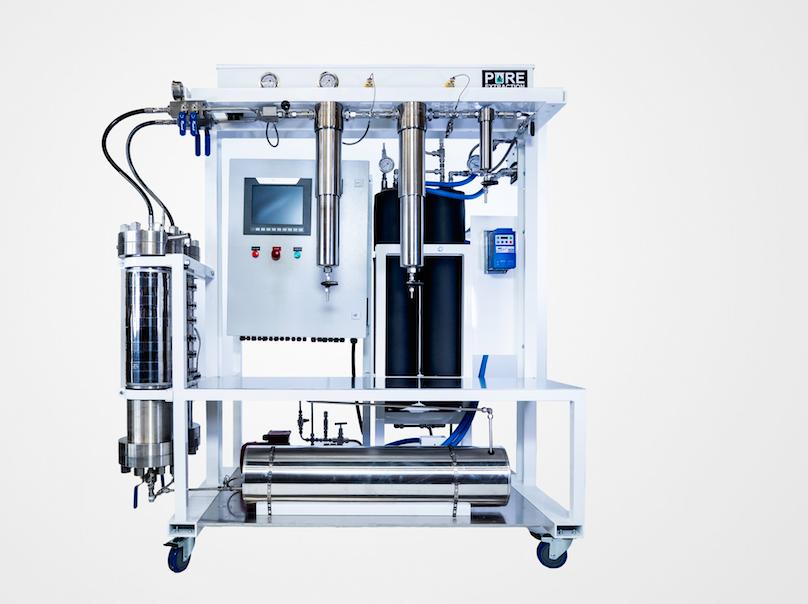

Supercritical CO2 extractor from Canadian extraction firm, Pure Extraction.

So Which Method Is Best?

The truth is that the best method is the one that suits both your business goals, and the experience and resources available to your extractor. Artisanal extraction methods are artistic and of high quality, however this relegates them to niche extract category. If that’s your goal, then these methods are suitable for making high quality products for a select group that appreciates the labour of love put into the extract.

Alternatively if you are looking to process a 100 acre field of hemp, you will likely require a commercial ethanol extractor. This can boost the required level of investment as the basic equipment for bubble bags or rosin press techniques is significantly less than a commercial ethanol extractor.

For all extractors there are a number of considerations prior to investing in any extraction equipment. Questions to consider include:

- What is your supply of starting material?

- Who are your customers?

- What is the scale at which you wish to extract?

- What is your space capable of handling in terms of size and power demands?

- What is your budget?

- How much time do you plan spending to perfect the craft?

The answers to all of these questions will help shape the best extraction lab setup for your ambitions and dreams.

Selecting the Right Extraction Method

Given the variety of extraction methods and how each may support your business goals, selecting the correct extraction method is critical. Whether you are looking to determine how extraction method impacts your plans, find solutions to streamline your operation, or are just starting to draft a business plan, GrowerIQ is here for you with software and a team of industry leading cannabis consultants to help you build and improve your business.

We make the process simple. Start now by submitting the form to the right, or start a chat with us. For more information, and actionable tips from our Master Grower on how to improve your yields and processes, please visit our GrowerIQ's cannabis consulting services page.

About GrowerIQ

GrowerIQ is changing the way producers use software - transforming a regulatory requirement into a robust platform to learn, analyze, and improve performance.

To find out more about GrowerIQ and how we can help, fill out the form to the right, start a chat, or contact us.