How well do you know cannabis facility sanitation? Prevention in a cannabis production facility is a vital part of keeping your business safe.

Production Standards for Medical Marijuana Medical marijuana is subject to different regulatory standards depending on location. For producers in the US and Canada, requirements get based on Good Agricultural Practices (GAP) and Good Manufacturing Practices (GMP) guidelines.

Read our previous article on Cannabis Batch Tracking to master your compliant grow

Read it nowRequirements for Canadian cannabis producers

At a minimum, producers need to follow simple food safety standards to ensure that production and handling do not introduce health hazards to the consumer. In Canada, producers must also comply with Good Production Practices (GPP) that require quality assurance programs and designated quality assurance auditors to execute the program. GPP applies to Licensed Producers and pays special attention to the control of microorganisms and pesticide use. GPP guidelines are part of the Canadian Cannabis Act and its predecessor the Access to Cannabis for Medical Purposes Regulations (ACMPR). Parts of the Canadian Food and Drugs Act also apply to medical marijuana producers in Canada.

Sanitation is a key part of all regulatory standards and is integral to having high-quality products. It is important to remember that cannabis is a medicine. Consumers are patients with illnesses and conditions that may compromise their immune systems, making it even more vital to ensure that the finished product is free from adulterations. Even recreational cannabis producers must abide by health and safety standards to ensure consumers are not harmed by the use of their products. Ensure you abide by the compliance checks in commercial cannabis cultivation with our guide.

Health hazards to look out for during facility sanitation

Health hazards are contamination risks that may result in illness, injury, or other harm to consumers. Contaminants, or adulterations, include any material that is not intended to be in the product.

These fall into three main categories:

- Biological hazards

- Chemical hazards

- Physical hazards

Biological

Biological hazards include:

- Bacteria (Salmonella, Shigella, Listeria, E. coli, and others)

- Parasites (Cryptosporidium, Giardia, Toxoplasma, nematodes, and others)

- Viruses (Hepatitis A, Norwalk Virus, Rotavirus)

Biological hazards get controlled and prevented by regular facility cleaning, good worker hygiene, and keeping environmental conditions like humidity at levels that do not encourage the growth of pathogenic microorganisms. When working with crops, consider biological hazards at all stages of production. If manure fertilizer gets used, follow strict regulations to avoid exposing workers and consumers to fecal contaminants. Pest control is also part of biological hazard control since pests can carry bacteria, viruses, and parasites.

Chemical

Chemical hazards come from materials like cleaning products, fertilizers, and pesticides. All chemicals used in a medical cannabis production facility should have safety data sheets (SDS or MSDS). Safety data sheets inform workers of the risks of using the chemical and how to handle it. Workers need to be aware of the risks associated with using chemicals, and facilities need to have plans for cleaning up spills and storing chemicals. Highly controlled pesticides are a chemical hazard in medical cannabis production. They are subject to a large amount of regulation that producers need to be in compliance with. Only a few pesticides get approved for use in cannabis production. Conducting tests on the final product ensure that consumers are not exposed to residues.

Physical

Physical hazards are materials such as nails and screws, broken equipment fragments, and pieces of wood or plastic that contaminate the final product. Physical hazards can be especially dangerous if the end product is consumable like edible cannabis products and oils. Proper maintenance and cleaning, along with inspection of final products should prevent the introduction of materials that will harm consumers when ingested. Personal effects like jewelry are especially concerning and production facilities should have dress codes that consider the potential for these items to contaminate the final product.

Dress codes and protective equipment

Worker hygiene is important because it minimizes biological, chemical, and physical hazards. Do not allow workers who are ill to work in areas of production that could lead to transmission of the illness. Producers should encourage sick employees to stay home. In addition to sick policies, workers should have easy access to handwashing stations and first aid kits. Personal hygiene rules should be in place to guide workers on what is acceptable. Dress codes help ensure that employees’ clothing does not pose a risk to production. Clean clothes, no jewelry, and short clean nails are common suggestions for GMP dress codes. Some facilities may also require lab coats, hair nets, gloves, and captive shoewear to reduce the possibility of carrying in contaminants on clothing.

Personal protective equipment (PPE) is an important part of worker and product safety. Different activities and production areas often have different standards.

Some examples of PPE common to medical cannabis production include respirators, gloves, and clothing covers used when applying chemicals like pesticides and fertilizers.

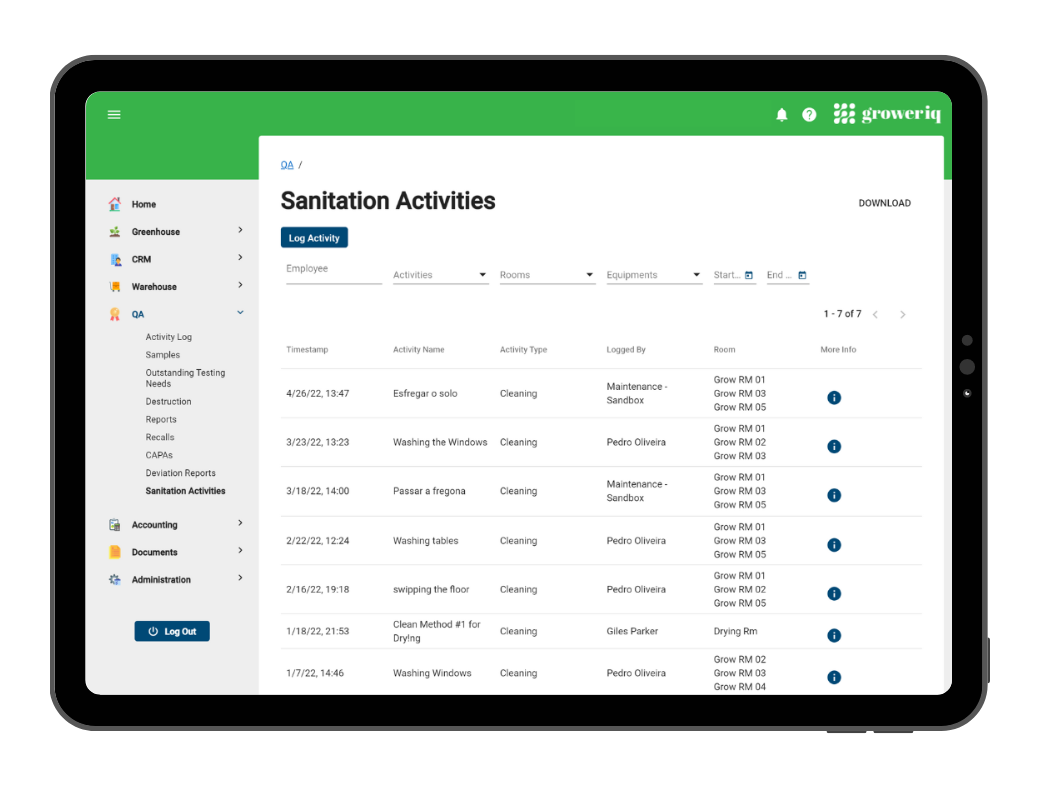

GrowerIQ’s cannabis software allows you to digitally track all of your facility sanitation activities in one place

Book a Demo NowCleaning and sanitation in medical cannabis production

Cleaning and sanitation are the foundation of cannabis plant diseases and hazard prevention. To have an effective sanitation program, use the right cleaners and the right tools at the right frequency. Additionally, medical cannabis producers should consider building materials and ventilation when designing their facilities. Using negative pressure and air curtains in entries prevents pests and foreign materials from entering production and processing areas, and using non-porous building materials and work surfaces allows for easy and effective cleaning.

General production area and cannabis storage facility cleanliness checklist

- Dispose of trash in a sanitary manner.

- Keep the landscape around buildings clean and free from weeds and trash, ensuring that no areas inside or outside the facility will provide habitats to pests and pathogens.

- Regularly change HVAC and irrigation filters – and perform maintenance and inspection of the building and production equipment.

- Keep facilities dry, and clean up standing water as fast as possible, since it is a breeding habitat for pests like mosquitos, bacteria, and mold.

Cleaning and sanitation programs

Everything in the facility should be on a cleaning program with special attention paid to surfaces that contact the product, floors, and walls.

Facilities should have three kinds of documentation for cleaning:

- Procedures – Tell workers how and when to clean.

- Performance logs – To perform and record the cleaning when scheduled.

- Schedules – State what needs cleaning, when it needs cleaning, and what products to use.

Different cleaning products get used for different purposes. In choosing cleaning products, consider the material getting cleaned and the hazard risk needs. Some cleaning agents will be more or less suitable for cleaning metals, glass, concrete floors, and other materials. Likewise, cleaning agents get graded by the extent to which they clean and have different active ingredients that are suitable for different target microorganisms. Thorough procedures are vital across greenhouse sanitation, cannabis production sanitation and cleaning cannabis.

Types of cleaning agents

Soaps and detergents remove soil, and disinfectants and sanitizers kill pathogens. Pathogens can build resistance to active ingredients, so cleaning schedules usually rotate the use of products with different active ingredients. Some of the most common active ingredients for disinfectants and sanitizers include chlorine bleach, quaternary ammonia, isopropyl alcohol, hydrogen peroxide, and peracetic acid.

Cleaning tools

Some areas of production can benefit from mechanized and automated cleaning by foaming, spraying, or pressure washing. More often cleaning will get performed manually by wiping, mopping, or soaking. Clean tools should always get used as dirty mop heads and wipes can spread more bacteria. Disposable single-use cleaning tools are ideal for cleaning medical production facilities because they ensure cleaning tools are not harboring pathogens. Some workers may want to reuse single-use equipment after light use, but this should be strictly prohibited.

Validation and testing

GAP, GMP, and GPP all require validation of sanitation to some extent. Validations prove that sanitation programs are working, that cleaning agents are being mixed and used properly, and that the correct organisms are being targeted. Environmental monitoring programs are usually a part of this. In environmental monitoring, a person (usually a quality assurance scientist), uses microbiology techniques like swabbing and petri dish settle plates to monitor workers, equipment, and the facility for bacteria. In addition, laboratory testing of final products ensures that the product is at acceptable levels for microorganisms and chemical residues.

Fundamentals of GAP, GMP, and GPP

- To capture the plant’s age and the plant’s batch initiation, use the next digits of the week of the year and the year.

- Examples:

- 1-18 for the week of January 1st, 2018

- 52-18 for the week of December 30th, 2018

- Examples:

- Medical marijuana producers must have:

- validated written sanitation procedures

- tracking and recall programs to address product complaints and contamination events

- Facilities should have/must be:

- maintained in good repair and in a clean and sanitary condition

- designed for easy cleaning and to lower the likelihood of introducing pests

- monitoring and surveillance procedures to identify problems as early as possible

- procedures for monitoring and controlling microbial organisms

- procedures for the safe use of rodenticides, insecticides, fungicides, fumigating agents, and cleaning and sanitizing agents

- Workers must have documented training in performing cleaning, sanitation, and other tasks that pose health hazards.

- Keep records and cleaning schedules to prove that producers are complying with their procedures and with cannabis regulations.

Facility sanitation for complete cannabis production compliance

Understand how to improve and monitor your cannabis production business facility sanitation and other necessary components with our seed-to-sale software.

Book a Demo NowAbout GrowerIQ

GrowerIQ is changing the way producers use software - transforming a regulatory requirement into a robust platform to learn, analyze, and improve performance.

To find out more about GrowerIQ and how we can help, fill out the form to the right, start a chat, or contact us.