Understand Why Cannabis Packaging is Important, The Various Cannabis Packaging Laws Throughout the World & Tips for a Streamlined Cannabis Packaging Process

In an industry that is growing at an unprecedented rate, the packaging of cannabis has become an art form in itself, ensuring not only compliance with regulations but also capturing the essence of the product within. From eco-friendly materials to innovative designs, we delve into the latest trends and techniques that make cannabis packaging a truly unique and exciting field.

What is the Goal of Cannabis Packaging from a Regulatory Standpoint

Regulators have a vested interest in tracking, tracing, and maintaining quality control at every stage of the cannabis lifecycle, from seed to sale. This level of oversight is crucial for several reasons. Firstly, regulators need to ensure that the cannabis being produced is safe for consumption. By implementing rigorous quality control measures, regulators can monitor the cultivation, processing, and distribution processes to minimize health risks to consumers.

Prevent Illicit Cannabis Sales

Regulators also want to prevent illegal activity such as diversion and black market sales. The illicit market not only undermines the legal cannabis industry but also poses potential risks to public health and safety. By tracking the entire lifecycle of each cannabis product, regulators can detect any discrepancies or suspicious activities that may indicate diversion or unauthorized sales.

Compliance with Local Laws

Furthermore, tracking and tracing systems help regulators ensure compliance with applicable laws and regulations. By implementing a robust system, regulators can monitor and enforce rules related to product testing, labelling, packaging, and advertising. This level of oversight ensures that consumers have accurate and reliable information about the products they are purchasing, including potency, ingredients, and potential risks.

Ease of Operations Across the Cannabis Supply Chain

Effective cannabis packaging also enables key stakeholders to track the seed-to-sale lifecycle of each cannabis product. Through the use of unique identifiers, barcodes, or QR codes, packaging can be scanned or tracked at each stage of the supply chain, providing valuable information about the product’s origin, cultivation, processing, and distribution.

Increasing Trust in the Cannabis Market

This level of transparency and traceability benefits various stakeholders. Regulators can easily verify compliance, identify any non-compliant products, and take appropriate enforcement actions. Cultivators can showcase their commitment to quality and adherence to regulatory standards, building trust and credibility with consumers. Distributors and retailers can ensure they are selling legally sourced and tested products, reducing their liability and reputational risks.

Cannabis Packaging Legal Requirements Throughout the World

Cannabis packaging plays a crucial role in the global cannabis industry, as it not only serves to protect the product but also ensures compliance with legal requirements. That being said, let’s take a look at an overview of the legal requirements for cannabis packaging in the largest global cannabis markets. You’ll notice some common themes very quickly.

1. United States

In the United States, cannabis is regulated at both the federal and state levels. Each state has its own specific packaging regulations, which can vary widely. Generally, cannabis packaging must be child-resistant, opaque, and labelled with specific information such as product potency, ingredients, and warning labels.

- Federal vs. State Regulation: Cannabis remains classified as a Schedule I controlled substance under federal law, which means it’s illegal at the federal level. However, a growing number of states have legalized the use of cannabis for medical and/or recreational purposes. This has led to a complex interplay between federal and state regulations.

- State-Specific Packaging Regulations: Since cannabis is primarily regulated at the state level, each state can have its own unique set of rules and requirements for cannabis packaging. This includes guidelines for the design, labeling, and safety features of cannabis packaging.

- Enforcement: Enforcement of these regulations typically falls under state regulatory agencies, such as state cannabis control boards or commissions. Businesses found in violation of packaging regulations may face fines, product recalls, or other penalties.

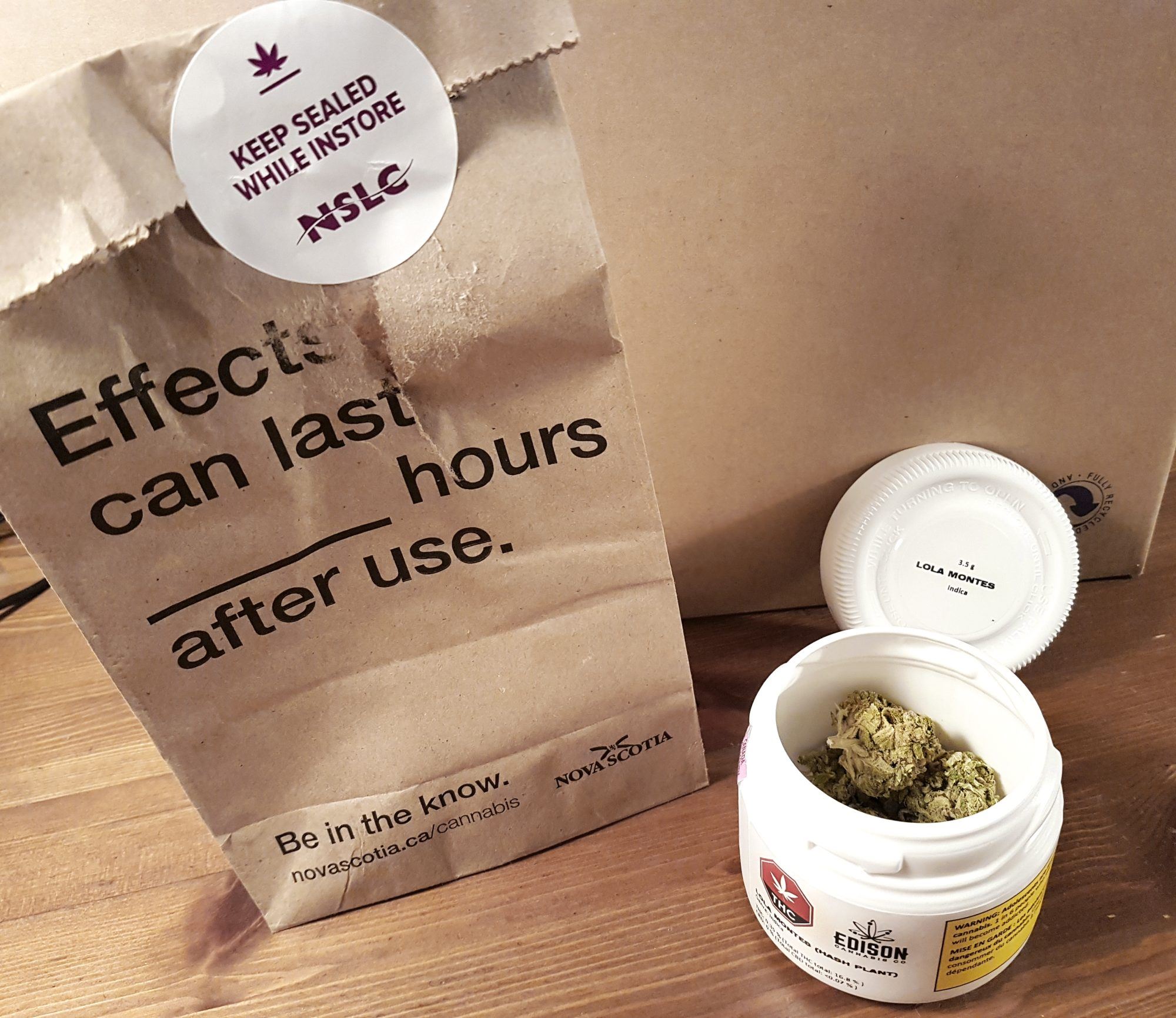

2. Canada

Canada legalized recreational cannabis in 2018 and has strict packaging regulations set by Health Canada. Packaging must be child-resistant, contain specific warning labels, and display standardized cannabis symbols. Additionally, plain packaging rules are enforced, meaning branding and advertising on packaging are limited.

- Lab Testing & QA Requirements: Licensed cannabis producers in Canada are required to adhere to strict quality assurance and testing standards to ensure the safety and consistency of their products. Packaging must accurately reflect the product’s contents and quality.

- Enforcement: Health Canada and provincial regulatory authorities oversee the enforcement of these packaging regulations. Non-compliance can result in fines, product recalls, or other penalties for cannabis producers and retailers.

3. Germany

Germany has one of the largest medical cannabis markets in Europe. Packaging must be child-resistant, tamper-evident, and include warning labels. Additionally, it must be labelled with information such as CBD and THC content, batch numbers, and expiration dates.

- Regulatory Authority: The Federal Institute for Drugs and Medical Devices (BfArM) is the regulatory authority responsible for overseeing the medical cannabis program in Germany. They establish and enforce regulations related to the cultivation, distribution, and packaging of medical cannabis.

- In addition to the information mentioned above, medical cannabis packaging in Germany must include the product’s name, the producer’s name and contact information, dosage instructions, and storage recommendations.

4. Australia

Australia’s cannabis industry is highly regulated, with packaging requirements varying by state. Generally, packaging must be child-resistant, include warning labels, and provide information on THC and CBD content, batch numbers, and expiry dates.

- Regulatory Authority: Australia’s cannabis industry is subject to a combination of federal and state regulations. While the federal government oversees the import and export of cannabis-related products, the individual states and territories have the authority to set their own regulations regarding cultivation, distribution, and packaging.

5. Columbia

Colombia has become a major player in the global cannabis market. Packaging must be child-resistant, tamper-evident, and include warning labels in Spanish. Additionally, it must display information such as THC and CBD content, batch numbers, and expiration dates.

- Colombia places a strong emphasis on quality control and traceability in the cannabis industry. This includes not only accurate packaging but also rigorous testing and tracking systems to ensure product safety and consistency.

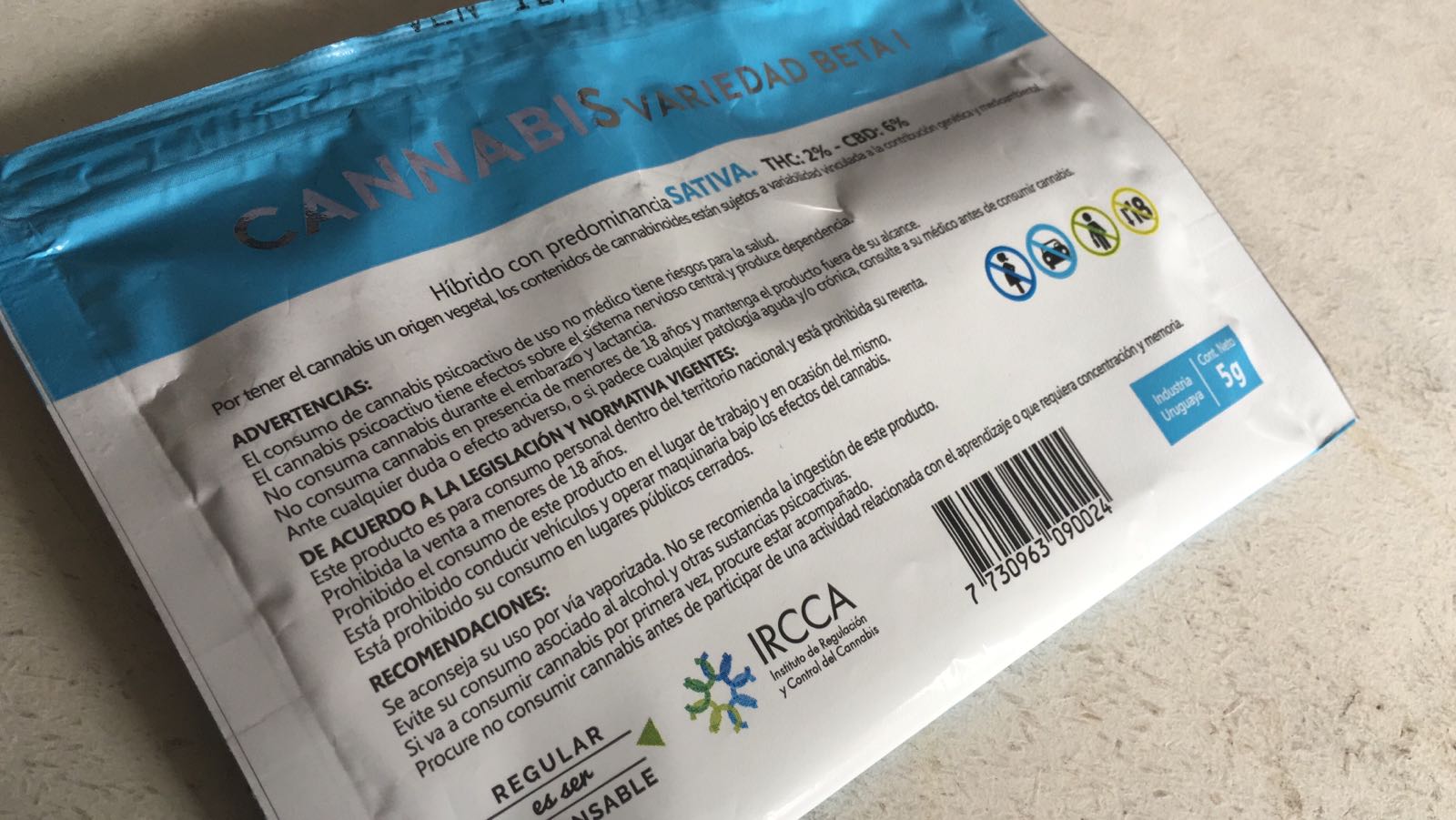

6. Uruguay

Uruguay was the first country to fully legalize cannabis. Packaging must be child-resistant and include specific warning labels. Additionally, it must display information on THC and CBD content, as well as the strain name.

- One unique aspect of Uruguay’s cannabis industry is the government’s role in overseeing cultivation, distribution, and sale. The country operates under a single-source model where the government controls the entire cannabis supply chain, from cultivation to sale. This includes packaging regulations.

- Unlike some other countries, Uruguay’s regulations require the inclusion of the strain name on cannabis packaging. This provides consumers with specific information about the genetic lineage and characteristics of the cannabis they are purchasing.

- In Uruguay, cannabis is primarily distributed through licensed pharmacies. As a result, packaging regulations are closely linked to the distribution model, ensuring that products are appropriately labeled and dispensed through authorized channels.

7. Israel

Israel has a well-established medical cannabis program. Packaging must be child-resistant and include warning labels. It must also display information on THC and CBD content, as well as instructions for use.

- In addition to labels, Israel often includes patient education materials with medical cannabis packaging. These materials provide patients with detailed information about the specific strain, potential side effects, dosage recommendations, and other important details to help them use the product safely and effectively.

- Israel is a diverse country with residents who speak various languages. To accommodate this diversity, medical cannabis packaging often includes labeling in multiple languages to ensure that all patients can understand the information provided.

- Israel is known for its innovative medical research and development. Cannabis packaging in the country may incorporate features designed to support ongoing research efforts, such as QR codes that link to research studies or patient outcomes data.

- Israel has specific regulations governing the import and export of medical cannabis products. Packaging must adhere to these regulations, which are in place to ensure the security and traceability of cannabis products entering and leaving the country.

8. Netherlands

The Netherlands has a long-standing cannabis tolerance policy. Packaging must be child-resistant and labelled with information on THC and CBD content, as well as strain names. Additionally, it must include warning labels and instructions for use.

- The Netherlands has specific regulations for cannabis sales in coffeeshops, which extend to packaging and labeling requirements. These regulations aim to maintain a clear distinction between legal and illegal cannabis sales and ensure consumer safety within the tolerated framework.

Spain

Spain has a decentralized approach to cannabis regulation, with different regulations in each region. Generally, packaging must be child-resistant and include warning labels. It must also display information on THC and CBD content, as well as strain names.

- Similar to Uruguay, a unique aspect of cannabis packaging in Spain is the requirement to display strain names. This is important for consumers who may have specific preferences or medical needs related to particular cannabis strains.

Italy

Italy has a growing medical cannabis industry. Packaging must be child-resistant and include warning labels. It must also display information on THC and CBD content, as well as batch numbers and expiration dates.

Related Reading

- Growing Cannabis

- Grow Room

- Cannabis Farming

- Cannabis Industry Trends

- Cannabis Act

- Cannabis Vertical Farming

Types of Products That are Packaged

When it comes to cannabis packaging, there are several different types of products that are typically packaged to meet the needs and preferences of consumers. These products range from flowers to concentrates, edibles, topicals, and more.

Cannabis Flowers

First and foremost, cannabis flowers are one of the most common types of products that are packaged. These are the dried and cured buds of the cannabis plant, which are usually inhaled through smoking or vaporizing. Flowers are often packaged in glass jars or airtight bags to preserve their freshness and potency.

Concentrates

Another popular type of cannabis product is concentrates. Concentrates are highly potent extracts of the cannabis plant that are made by extracting the cannabinoids and terpenes from the flowers. They come in various forms, such as oils, waxes, and shatter. Concentrates are typically packaged in small, airtight containers to prevent oxidation and maintain their potency.

Edibles

Edibles are another type of cannabis product that are commonly packaged. These are food products infused with cannabis, such as cookies, brownies, gummies, and beverages. Edibles are usually individually wrapped or packaged in child-resistant containers to ensure safe consumption and prevent accidental ingestion by children or pets.

Topicals

Topicals are cannabis-infused products that are applied to the skin for localized relief. These can include balms, creams, lotions, and transdermal patches. Topicals are typically packaged in containers with precise dosage instructions and are often designed for easy application.

Other Products

In addition to these main categories, there are many other cannabis products that are packaged, such as pre-rolls (pre-rolled joints), tinctures (liquid cannabis extracts), capsules, and more. Each of these products has its own unique packaging requirements to ensure freshness, potency, and compliance with regulations.

Related Reading

- Cannabis Manufacturing

- Cannabis Licensing Application Guide

- Cannabis Courses

- List Of Licensed Producers In Canada

Pro-Tip that Will Set Up an Effective Cannabis Packaging Process

Cannabis producers that utilize seed-to-sale cannabis software have revolutionized the packaging process for distributors, wholesalers, and retailers. By employing this technology, these producers can effectively track and report on each lifecycle stage of their cannabis products. This level of transparency is not only useful but also extremely helpful for key stakeholders in the cannabis market.

The ability to track and report on each lifecycle stage of cannabis products through seed-to-sale cannabis software is incredibly valuable for distributors, wholesalers, and retailers. It ensures transparency, quality control, and compliance with regulations. This technology empowers key stakeholders in the cannabis market to make informed decisions, provide better customer experiences, and ultimately contribute to the growth and legitimacy of the industry.

Did you know? GrowerIQ has an industry-leading Seed-to-Sale Cannabis Software (with quality management built in) that is designed to uncomplicate cannabis production for cannabis producers throughout the world.

Cannabis Packaging Methods & Key Cannabis Packaging Trends

Cannabis packaging comes in a variety of forms, each serving a specific purpose in the industry. Let’s take a look at some of the more popular, current packaging methods.

1. Glass Jars

Glass jars are a popular choice due to their ability to prevent moisture and odor transfer, while allowing consumers to inspect the product. Borosilicate tube jars offer similar benefits and are often used for pre-rolls, ensuring they remain fresh and intact.

2. Smell-Proof Containers

Smell-proof bags are commonly used for discrete storage and transportation of cannabis products. These bags are designed to trap odors, preventing them from escaping and alerting others to the contents. Borosilicate glass containers are also scent-resistant, making them ideal for concentrates and other high-potency products.

3. Polystrene Containers

Polystyrene containers are lightweight, shock-resistant, and offer good insulation. They are often used for edibles and other perishable items to protect them from external factors such as heat and moisture. Acrylic containers are visually appealing and provide a transparent display of the product, allowing customers to see what they are purchasing.

4. Silicone Containers

Silicone containers are flexible and durable, making them perfect for storing sticky or oily extracts. Their non-stick properties ensure that no product is wasted, and they are easily cleaned for reuse. Tube jars, on the other hand, are designed for convenient and compact storage of pre-rolls. They protect the joints from damage and maintain their freshness.

Consumer-Centric Bags

Single-use bags and resealable bags are versatile options for different products. Single-use bags are often used for individual servings of edibles, while resealable bags are ideal for preserving flower buds and preventing moisture loss. Pop-top tubes provide a child-resistant packaging solution for edibles and other cannabis products.

Clear Tubes

Clear tubes are not only visually appealing but also allow customers to see the product inside. They are often used for pre-roll joints to showcase the quality of the flower. Pre-roll bags, similar to smell-proof bags, provide a discreet and portable option for pre-rolls.

Growing Trends in the Cannabis Packaging Industry

As the cannabis industry grows, there is a noticeable push towards sustainable and eco-friendly packaging methods. This shift is driven by a desire to reduce waste, minimize environmental impact, and meet consumer demands for responsible practices. Many cannabis companies are embracing sustainable packaging materials such as recycled paper, hemp-based plastics, and biodegradable materials.

Minimalism

Minimalism has become a popular trend in cannabis packaging, reflecting a clean and modern aesthetic. Simple designs and minimal use of color and text are favored, emphasizing the quality of the product itself. Artisanal and craft-brand oriented packaging is also gaining traction, appealing to consumers who appreciate small-batch, handcrafted products. This type of packaging often showcases unique design elements and highlights the story behind the brand.

Artisinal or Craft Packaging

With the advent of cannabis 2.0 niche markets, packaging has become an important tool for differentiation. Niche markets such as organic, low-dose, and high-CBD products require packaging that reflects their specific attributes. These products often feature specialized labels, certifications, and branding elements to attract and inform the target audience.

Related Reading

- Growing Cannabis Indoor

- Wholesale Cannabis

- Micro Cultivation Building Requirements

- Cannabis Podcast

- Cannabis Packaging Canada

Common Risks with Cannabis Packaging

When it comes to cannabis packaging, there are several common risks that manufacturers and producers need to be aware of. These risks can affect the quality and safety of the product, as well as the overall customer experience. It is crucial to understand and address these risks in order to ensure that the cannabis products reach the consumers in the best possible condition.

Contamination

Cannabis is a sensitive plant, and any contact with contaminants can affect its quality and potency. Contaminants can come from various sources, such as the packaging materials themselves or the handling and storage processes. Mold, bacteria, and other microorganisms can proliferate if the packaging is not properly sealed or if it is exposed to excessive moisture or heat. This can lead to the degradation of the product and potentially harmful effects on the consumer.

Improper Labelling

Another risk is improper labelling. Cannabis products need to be accurately labelled with important information, such as the strain, THC and CBD levels, dosage instructions, and any potential allergens. Improper or misleading labeling can lead to confusion among consumers, and in some cases, even legal consequences. It is essential that the packaging clearly and accurately communicates all the necessary information to ensure customer safety and compliance with regulations.

Inadequate Child-Resistant Packaging

Additionally, inadequate child-resistant packaging is a significant risk in the cannabis industry. Many jurisdictions require cannabis products to be packaged in child-resistant containers to prevent accidental ingestion by children. Failure to comply with these regulations can result in legal penalties and reputational damage. It is crucial for manufacturers to invest in child-resistant packaging solutions that are effective and easy to use for adults, while still ensuring the product’s freshness and quality.

Industry Best Practices for Cannabis Packaging

To mitigate the risks associated with cannabis packaging, there are several industry best practices that manufacturers and producers should follow. These practices help ensure the quality, safety, and compliance of the product, while also enhancing the overall customer experience.

Using High-Quality Packaging Materials

The packaging should be made of materials that are safe, durable, and resistant to contamination. It is important to choose materials that have been tested and approved for use with cannabis products. This includes considering factors such as light and moisture resistance, as well as the potential for leaching of harmful chemicals into the product.

Tamper Proof Packaging

The packaging should provide a secure seal that protects the product from external contaminants and ensures its freshness. Additionally, tamper-evident features such as seals or tear strips can help consumers identify if the packaging has been tampered with, further enhancing their trust in the product.

Accurate & Clear Labelling

The label should include all the required information, such as the strain, THC and CBD levels, dosage instructions, and any potential allergens. Clear and legible fonts, along with informative graphics, can help consumers easily understand the information provided. It is also important to ensure that the label remains intact and legible throughout the product’s lifespan, as damaged or faded labels can lead to confusion and potential misuse.

How Seed-to-Sale Cannabis Software Helps Streamline the Cannabis Packaging Process

GrowerIQ’s seed-to-sale cannabis software revolutionizes the packaging process by providing batch-tracking with automated reporting and one-click packing slips and bill of materials. This comprehensive software solution is precisely what cannabis producers need to ensure compliance with packaging requirements across the globe.

One of the main challenges faced by cannabis producers is maintaining accurate records throughout the packaging process. With GrowerIQ’s software, batch-tracking becomes effortless. Every step, from cultivation to harvest, post-harvest processing, and packaging, is meticulously documented. This level of traceability ensures that producers can easily prove the origin and quality of their products, a crucial aspect for gaining consumer trust and complying with regulatory standards.

The one-click packing slips and bill of materials feature significantly streamlines the packaging process. Cannabis producers often face strict labelling and documentation regulations, making packaging a complex and time-consuming task. However, with GrowerIQ’s software, producers can quickly generate packing slips and bills of materials, ensuring compliance with labelling requirements. This feature eliminates the need for manual data entry and reduces the risk of errors, further improving efficiency and accuracy.

Discover how GrowerIQ’s seed-to-sale software can help you set up all of the components of a successful cannabis production operation without any hassle. Questions we haven’t covered? Please reach out and let us know. GrowerIQ serves clients coast to coast, and we’re ready to help your team today.

Streamline Cannabis CultivationAbout GrowerIQ

GrowerIQ is changing the way producers use software - transforming a regulatory requirement into a robust platform to learn, analyze, and improve performance.

To find out more about GrowerIQ and how we can help, fill out the form to the right, start a chat, or contact us.